de Havilland Mosquito

| DH.98 Mosquito | |

|---|---|

|

|

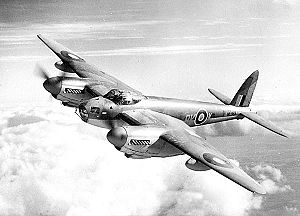

| The Mosquito B.Mk XVI ML963 - this aircraft was lost on an operation to Berlin in April 1945 | |

| Role | Fast bomber fighter-bomber night fighter maritime strike fast photo reconnaissance aircraft |

| Manufacturer | de Havilland Aircraft Company |

| First flight | 25 November 1940[1] |

| Introduction | 1941 |

| Status | retired |

| Primary users | Royal Air Force Royal Canadian Air Force Royal Australian Air Force United States Army Air Forces |

| Produced | 1940–1950 |

| Number built | 7,781.[2] |

The de Havilland DH.98 Mosquito was a British combat aircraft that excelled in versatility during the Second World War. It was known affectionately as the "Mossie" to its crews[3] and was also nicknamed "The Wooden Wonder" or "The Timber Terror" as the bulk of the aircraft was made of laminated plywood.[4] It saw service with the Royal Air Force (RAF) and many other air forces in the European theatre, the Pacific theatre of Operations and the Mediterranean Theatre, as well as postwar.

Originally conceived as an unarmed fast bomber, the Mosquito was adapted to many other roles during the air war, including: low to medium altitude daytime tactical bomber, high altitude night bomber, pathfinder, day or night fighter, fighter-bomber, intruder, maritime strike, and fast photo reconnaissance aircraft carrying out aerial reconnaissance. It was even used by the British Overseas Airways Corporation (BOAC) as a transport. It was also the basis for a single-seat heavy fighter, the de Havilland Hornet.

Upon the Air Ministry's decision to enter the Mosquito into production in 1941, it was the fastest operational aircraft in the world.[5] Entering widespread service in 1942, the Mosquito supported RAF strategic night fighter defence forces in the United Kingdom from Luftwaffe raids, most notably defeating the German aerial offensive Operation Steinbock in 1944. Offensively, the Mosquito units also conducted night time fighter sweeps in indirect and direct protection of RAF Bomber Command's bomber fleets to reduce RAF bomber losses in 1944 and 1945. The Mosquito increased German night fighter losses to such an extent the Germans were said to have awarded two victories for shooting one down.[6] As a bomber it took part in "special raids", such as pinpoint attacks on prisoner-of-war camp, Gestapo or German intelligence and security force bases as well as tactical strikes in support of the British Army in the Normandy Campaign. Some Mosquitos also saw action in RAF Coastal Command during the Battle of the Atlantic, attacking Kriegsmarine U-Boat and transport ship concentrations, particularly in the Bay of Biscay offensive in 1943 in which significant numbers of U-Boats were sunk or damaged.

It was famously praised by Hermann Göring, whose remarks are usually translated as:

"In 1940 I could at least fly as far as Glasgow in most of my aircraft, but not now! It makes me furious when I see the Mosquito. I turn green and yellow with envy. The British, who can afford aluminium better than we can, knock together a beautiful wooden aircraft that every piano factory over there is building, and they give it a speed which they have now increased yet again. What do you make of that? There is nothing the British do not have. They have the geniuses and we have the nincompoops. After the war is over I'm going to buy a British radio set - then at least I'll own something that has always worked."

– Hermann Göring, 1943.[7][8]

Contents |

Design and development

Earlier designs

Throughout the 1930s, de Havilland established a reputation in developing innovative high-speed aircraft such as the DH.88 Comet mailplane and DH.91 Albatross airliner that had already successfully employed the composite wood construction that the Mosquito would use. The construction of their aircraft compensated for the general low power of aero engines available at the time. The 22-passenger de Havilland DH.91 Albatross was capable of cruising at 210 mph (338 km/h) at 11,000 ft (3,350 m). The wooden construction and stressed skin covering not only saved weight and compensated for the low power engines, but simplified production and enabled a fast construction rate.[9]

The potential of their construction techniques could be seen in the design of the DH.88, which heavily influenced the Mosquito. In October 1934, the purpose-built Comet Racer C-ACSS Grosvenor House won the London-Melbourne Centenary Air Race, flying 11,300 miles (18,180 km) in 70 hours 54 minutes and 18 seconds.[10][11] Later, the aircraft flew from Gravesend to Sydney, Australia before flying to Blenheim, New Zealand in 10 days, 21 hours, 22 minutes, covering a distance of 26,450 miles (42,566 km).[11]

Just under two years later, de Havilland took an interest in Air Ministry specification P.13, issued on 8 September 1936 which asked for a twin-engined "medium bomber" suitable for "worldwide use" which could carry a 1,000 pound (450 kg) bombload for 1,000 miles while operating at 15,000 feet (4,600 m) and 275 miles per hour (443 km/h) and a maximum 8,000 lb (3,630 kg) bombload. Major aviation firms entered heavy designs with new high-powered engines and multiple defensive turrets, but de Havilland felt that a smaller aircraft could do the same job.[12] The firm had little experience of working with the Air Ministry, and their all-wood approach was considered to be out of keeping with official policy.[13] P.13 would instead lead to the Avro Manchester and Handley Page Halifax.

Concept and design

In 1937, the concept of a fast unarmed bomber including a design comparable to P.13/36, was put before the Air Ministry by Volkert of Handley Page. Within the RAF it had support as an idea worth pursuing in case the need appeared as well as raising concerns that the (economic) benefits over conventional bombers were marginal given the limited operational role it could play.[14] The Ministry was also considering the maximum use of non-strategic materials for aircraft production, leading to the development of the Albemarle medium bomber which was largely constructed from spruce and plywood[15] on a steel tube frame.[16]

Although de Havilland wanted to go further than the original P.13 requirement, at first he looked at bomber adaptions of existing designs, such as the Albatross airliner. Eventually however, de Havilland settled on a new design for a twin-engine wood constructed bomber. It would be aerodynamically clean and powered by the Rolls-Royce Merlin engine which even at that early point, offered huge promise. The original plan of the Mosquito was to be faster than enemy fighter aircraft, and therefore not need a defensive armament consisting of gun turrets, which in turn would slow it down and make interception more likely. This was in complete opposition to contemporary RAF design philosophy, which required well-armed heavy bombers (it was much more akin to the German schnellbomber concept). The design received the designation DH.98.[17]

The de Havilland design was deemed radical by the Air Ministry and received several rejections owing to the RAF desire for heavy well-armed bombers.[18] The last frontline operational aircraft the RAF had taken from de Havilland was the DH.9a.[19] The RAF required an aircraft that could act as a heavy bomber and a long range aircraft, and had sufficient speed to reduce the time spent over defended airspace. The priority given to speed was emphasised - one basic design able to combine medium bomber capability with reconnaissance and "general purpose" classes. The aircraft was also to be capable of maritime strike, so specifications for torpedo carrying equipment were to be part of this new design. In addition, the Ministry suggested two forward and two rear firing machine guns for defence.[10] The Air Council then applied further requirements, such as remotely controlled guns, and a top speed of 275 mph (442 km/h) at 15,000 ft (4,570 m) on two-thirds engine power and a range of 3,000 miles (4,830 km) with a 4,000 lb (1,810 kg) bomb load.[10]

In April 1938, de Havilland's initial design had started off as an adaptation of the Albatross, armed with three gun turrets and a six-man crew, and powered by two Rolls-Royce Merlin engines.[4] It would carry 6,000 lb (2,720 kg) of bombs to Berlin and back at 11,000 ft (3,350 m). Geoffrey de Havilland was concerned that the Air Ministry would not allow a design constructed of wood carrying bombs 3,000 miles (4,830 km) in wartime. On 7 July, he sent a letter to Air Marshal Wilfred Freeman, an old friend of de Havilland since the First World War, and now the Air Council's member for Research and Development, asking for help in case of opposition. Freeman gave the plans the green light.[10]

The Albatross design produced would need at least a three man crew and six to eight forward firing guns and a couple of handheld defensive weapons, with provision for a rear turret. All this produced a total weight of 19,000 lb (8,616 kg), a top speed of 300 mph (483 km/h) and cruise speed of 268 mph (431 km/h) at 22,500 ft (6,860 m). Geoffrey de Havilland considered this impossible for the time being, and expected the aero companies in Britain to struggle with the specifications of P.13/36. As it transpired, the Avro Manchester and Handley Page HP.56 were problematic designs[10] because of the problems with the Rolls-Royce Vulture. Changing to four Merlins gave the successful Lancaster and Halifax.

Ronald Bishop, de Havilland designer, sketched out the Mosquito at Salisbury Hall. Bishop had worked on the Comet under de Havilland's chief designer and the Albatross under A. E. Hagg.[20]

Later development, the Mosquito design takes shape

The restrictive design features placed upon the P.13 specification prompted de Havilland to approach the medium bomber project with a radical new design. They decided to eradicate the defensive armament altogether as it would save one-sixth the total weight of the aircraft. In consequence, production would be easier and faster with a delivery rate far in advance of any competing designs. Without armament, the crew could be reduced to two, a pilot and a navigator. The chief designer, Ronald Eric Bishop, made provision for the addition of 20 mm cannon installed in the nose. This forward firing heavy armament proved very successful in wartime.[21]

The Air Ministry was not happy with de Havilland's proposals. They wanted a bomber to conform to their concept that heavily-armed formations of bombers would make it through to their targets. On 27 July 1938, de Havilland distanced themselves further by stating the P.13 specification could not be met by a two Merlin engine aircraft unless the Air Ministry only wanted half of the 4,000 lb (1,810 kg) bomb load, otherwise a larger and slower bomber would be needed.[21] During the Munich Crisis in September 1938, the de Havilland company presented their brand new design which was manned by two crew and powered by two Merlins without any defensive armament. Speed, de Havilland vowed, would be its defence. In the First World War, de Havilland was satisfied that the Airco DH.4 bomber was able to outpace the fighters of the day. The wood design would also shave a year off the time it would take to build a metal prototype.[21]

In October 1938, the Ministry rejected de Havilland's proposal, sceptical about the idea of a wooden aircraft and the concept of the unarmed bomber.[4] The Air Ministry were interested only in all-metal bombers that could defend themselves with their heavy defensive armament. To accommodate them, de Havilland built a series of mock-ups with a turret installed in the fuselage armed with two machine guns. But other than this, the de Havilland company refused to change the fundamentals of the design.[21] On 20 September 1939, de Havilland wrote to Freeman again:

We believe we can produce a twin-engined bomber which would have a performance so outstanding that little defensive equipment would be needed. This would employ the well tried out method of construction used in the Comet and Albatross and being of a wood or composite construction would not encroach on the labour and material used in the expanding RAF. It is especially suited to really high speeds because all surfaces are smooth, free from rivets, overlapped plates and undulations and it also lends itself very rapid and subsequent production.[21]

In November 1939[21], de Havilland were progressing through various schemes using different engines and considering the effects of defensive armament on their designs.[22] A four-gun turret defence was possible with Griffon engines while keeping speed up. The Ministry were still supportive for the aircraft for development purposes, but availability of engines and turrets would make production of any more than the prototypes impracticable.[22] Rather than commit the design team to a single aircraft, 50 Merlin-engined DH.98s and two turreted prototypes were decided upon. At a meeting considering de Havilland's, Blackburn's and Bristol's fast bomber ideas in November, Wilfrid Freeman gained support for directing deHavilland to produce a fast aircraft with increasing power, firstly with Merlin engines, then RR Griffons, and after that Napier Sabres.[23]

Freeman was supportive and agreed to the lack of armament but doubted de Havilland's performance estimates which claimed a two crew wooden twin engine bomber could fly 1,500 miles (2,410 km) and at a speed faster than a Spitfire. He did believe, by using ducted air radiators and faired propeller roots, the aircraft could reduce drag to a large extent.[21] Despite the agreement there was still strong opposition to a two crew bomber, the Air Ministry wanted at least a third crewman to reduce the workload of the others on long flights.[21]

On 12 December 1939, the Vice-Chief of the Air Staff, Director General of Research and Development, Air Officer Commanding-in-Chief (AOC-in-C) of RAF Bomber Command met to thrash out the details of the design and its uses for future strategy. The AOC-in-C would not accept an unarmed bomber, but insisted it would be suited for reconnaissance missions with F24 cameras.[24] On that day, the Air Council ordered the DH.98 prototype built under specification B.1/40.[25]

After more talks between the company and Air Ministry and operational commands, on 29 December 1939, the project received official backing when the Air Ministry asked for a "basic" bomber requirement for a bomber capable of carrying a 1,000 lb (450 kg) bomb load and with a range of 1,500 miles (2,410 km). Finally, on 1 January 1940, a further meeting, chaired by Air Marshal Wilfrid Freeman took place with Geoffrey de Havilland, John Buchanan, Deputy of Aircraft Production and John Connolly, Buchanan's chief of staff. Claiming the Mosquito was the "fastest bomber in the world", de Havilland added "it must be useful". Freeman supported its production for RAF service and ordered a single prototype for an unarmed bomber variant to specification B.1/40/dh, powered by two Merlin engines. The aircraft was to have a speed of 397 mph (639 km/h) at 23,700 ft (7,220 m) and a cruising speed of 327 mph (527 km/h) at 26,600 ft (8,110 m) with a 1,480 mile (2,380 km) range at 24,900 ft (8,500 m) on full tanks. Maximum service ceiling was to be 32,100 ft (9,780 m).[24]

Project Mosquito

Air Marshal Roderic Hill ordered a contract for 50 DH.98 aircraft, including one prototype, which was finally placed under Specification B.1/40 on 1 March 1940. Design and prototype construction was able to begin almost immediately, but work was cancelled again after the Battle of Dunkirk in order to focus on existing types.[24]

Instead, the Supermarine Spitfire, Hawker Hurricane, Vickers Wellington, and Bristol Blenheim aircraft got priority. It was decided there was no production capacity for aircraft like the DH.98, which was not expected to be in service until early 1941. This was mostly as a result of the shortage of Merlin engines which were needed in fighter aircraft. The Mosquito was only reinstated as a priority in July 1940 after de Havilland promised Lord Beaverbrook 50 machines by December 1941; although de Havilland knew this was unlikely. Only 20 Mosquitos were built that year.[24] During this time Beaverbrook, as Minister for Aircraft Production, asked Air Marshall Freeman to cease work on the project. Freeman did not issue such an order but it seemed the project would be shut down when the design team were denied the materials with which to build their prototype. Only when Beaverbrook was satisfied that work would not divert effort from the repairing of Merlin engines and production of Tiger Moth trainers, was it allowed to continue.[26]

The Battle of Britain raged while the prototypes were being built, and 25% of the factory time was lost in the bomb shelters.[27] Nevertheless, the original day bomber prototype, W4050, was rolled out on 19 November 1940, and first flew on 25 November, only 10 months after the go-ahead. The original estimates were that as the Mosquito prototype had twice the surface area and over twice the weight of the 1940 Spitfire Mk II, but also with twice its power, the Mosquito would end up being 20 mph (32 km/h) faster. Over the next few months, W4050 surpassed this estimate, easily besting the Spitfire Mk II in testing at RAF Boscombe Down in February 1941 at a top speed of 392 mph (631 km/h) at 22,000 ft (6,700 m) altitude, compared to a top speed of 360 mph (579 km/h) at 19,500 ft (6,000 m) for the Spitfire. It also bested the Spitfire at low to medium altitude, some 6,000 ft (1,830m).[1]

The Air Ministry was still not happy with the concept of the unarmed bomber. Nevertheless, in the aftermath of the Battle of Britain, interest in long-range heavy fighter and bomber destroyers began. The original 50 prototype order was changed to 20 bomber variants and 30 fighters; it was still uncertain whether the fighter version should have dual or single controls or should carry a turret so three prototypes were required. This caused some delays as half built wing components had to be strengthened for the expected higher combat load requirements. The nose sections also had to be altered, from clear perspex, to solid noses designed to hold heavy air-to-air combat weapons.[18]

Prototypes and test flights

Construction of a prototype fighter version was carried out at the secret Salisbury Hall facility. The prototype was given the factory serial E-0234 and later allocated the military serial W4050.[18]

During testing, it was found that the day bomber prototype had the power and internal capacity to carry not the 1,000 lb (450 kg) of bombs originally specified but four times more. In order to better support the higher loads the aircraft was capable of, the wingspan was increased from 52 ft 6 in (16.0 m) to 54 ft 2 in (16.5 m). It was also fitted with a larger tailplane in comparison to later production types, an improved exhaust system, and lengthened nacelles that improved stability. These modifications became standard across the production versions. The skin on the tail surfaces was all wood and plywood covered, while the rudder and elevators were made of aluminium, and the elevators fabric covered. In 1943, the elevators were covered in metal to increase speed in dives. Two Merlin 21 two-speed single stage supercharged engines were installed. The propellers were de Havilland Hydromatic constant-speed three-blade airscrews.[28]

On 3 November 1940, the aircraft was transported by road to Hatfield, where it was placed in a small blast-proof assembly building, where successful engine runs were made on 19 November. On 24 November 1940, taxiing trials were carried out by Geoffrey de Havilland Jr, who was the chief test pilot and responsible for maiden flights. The tests were successful and the prototype was subsequently readied for flight testing. On 25 November, the aircraft made its first flight, piloted by Geoffrey De Havilland Jr., who flew W4052 off a 450-foot (140 m) field beside the shed it was built in. The flight was made 11 months after the start of detailed design work, a remarkable achievement under the conditions of the time (without the assembly line method).[18]

John E. Walker, Chief Engine Installation designer, accompanied de Havilland. The take-off was "straight forward and easy". The undercarriage was not retracted until a considerable height was obtained. The aircraft reached 220 mph (354 km/h), and the only problem was the failure of the undercarriage doors to fully close. They remained open by some 12 in (31 cm) as speed increased. This problem persisted for some time. Another teething problem was the inability of the tailwheel to caster properly, which caused the airframe in the rear fuselage to fracture during tests at Boscombe in 1941. This problem was solved in June - July 1941 by the fitting of a Dowty unit. The left wing of E-0234 had a tendency to drag to port slightly, so a rigging adjustment was carried out before further flights.[28]

On 5 December 1940, the E-0234, now with the serial W4050, experienced tail buffeting at speeds of 240-255 mph (386–410 km/h). The pilot noticed this most in the control column, and handling became more difficult. After de Havilland design staff explored the problem, the conclusion was it was a stall generating, away from the engine nacelles and on the underside of the wing. The disturbed airflow was striking the tailplane, causing the buffeting. Slots were fitted to smooth the air flow and deflect it from striking the tailplane with such force. Wool tufts were attached to the suspect areas as well during testing to investigate direction of airflow. The slots failed to achieve anything. The buffeting was eliminated by introducing stretched nacelles which extended back beyond the trailing edge of the wing, in February 1941. This meant the flaps had to be divided into inboard and outboard sections.[29]

With teething problems largely solved, John Cunningham flew W4050 on 9 February 1941. He was greatly impressed by the lightness of the controls and generally pleasant handling characteristics". Cunningham concluded that when the type was fitted with radar, it would be a perfect replacement for the Beaufighter.[29]

During its trials on 16 January 1941, W4050, in a bomber/reconnaissance configuration, the prototype outpaced a Spitfire at 6,000 ft (1,830 m). During February, the main priority was speed trials in level flight, during which it reached 390 mph (627 km/h) at 22,000 ft (6,700 m). Official trials began at Boscombe Down on 19 February which satisfied the de Havilland company. On 20 April 1941, it was demonstrated to Lord Beaverbrook, the Minister of Aircraft Production. The Mosquito made a series of flights, including one rolling climb on one engine. Also present were General Henry H. Arnold and his aide Major Elwood Quesada:

I do recall the first time I saw the Mosquito as being impressed by its performance, which we were aware of. We were impressed by the appearance of the airplane that looks fast usually is fast, and the Mosquito was, by the standards of the time, an extremely well streamlined airplane, and it was highly regarded, highly respected.[29]

The trials set up future production plans between Britain, Australia and Canada. The Americans did not pursue their interest. It was thought the Lockheed P-38 Lightning could handle the same duties just as easily. Arnold felt the design was being overlooked, and urged the strategic personalities in the United States Army Air Force to learn from the design if they chose not to adopt it. The USAAF then requested one airframe to evaluate, on 12 December 1941 after the Attack on Pearl Harbour, and the USAAF entered the war without a fast dual-purpose reconnaissance machine.[30]

W4051 was to be the second prototype, but an airframe fracture in W4050 meant that W4051's airframe was used as a replacement. W4051 received a production standard fuselage and actually saw combat operations. W4050 flew on 10 June 1941, the third Mosquito after W4052, which flew on 15 May 1941. W4055 flew the first operational Mosquito flight on 17 September 1941.[30] During the flight testing, the Mosquito was fitted with a number of innovations. W4050 was fitted with a turret behind the cockpit for drag tests. It was not adopted and the idea was abandoned in July 1941. W4052 had the first version of the Youngman Frill airbrake fitted to the fighter prototype. The frill was opened by bellows and venturi effect to provide rapid deceleration during interceptions and was tested between January - August 1942, but was abandoned when it was discovered that lowering the undercarriage had the same effect.[30]

W4052 was extensively used as the fighter variant prototype. It differed from its bomber brethren in a number of ways. It was powered by an upgraded variant of the Merlin 21 of 1,460 hp (1,088 kW), and also had a flat bullet-proof windshield. It was tested with powerful armament such as 40 mm cannon and other modifications, bomb racks, fuel drop tanks, barrage balloon cable cutters in the leading edge of the wings, Hamilton airscrews and braking propellers, as well as drooping aileron systems which enabled steep approaches, and a larger rudder tab. The prototype continued to serve as a test machine until it was scrapped on 28 January 1946.[5]

W4050 continued to be used for long and varied testing programs. In June 1942, it was powered by two Merlin 61s, a two-stage supercharger powerplant. It was used to eliminate problems on W4052. Most of this related to the former's exhaust and armament systems. Flash eliminators had to be fitted to the NF.II to prevent the crew from being blinded by muzzle flash during the firing of the weapons. The cooling intake shrouds that were to cool the exhausts overheated after a while. Flame dampers prevented the exhaust glow on night operations, but they had an effect on performance. Multiple ejector and open-ended exhaust stubs configuration solved the problem and were used in the PR.VIII, B.IX and B.XVI variants. This increased speed performance in the B.IX alone by 10-13 mph (16–21 km/h).[5]

By the time testing was over and the Air Ministry had authorised mass production plans to be drawn up on 21 June 1941, the aircraft was the world's fastest operational aircraft.[5] The Air Ministry authorised 19 PR. models and 176 fighters. A further 50 were unspecified. In July 1941, the Air Ministry confirmed these would be unarmed fast bombers.[5] The Mosquito would enjoy its fastest aircraft status for another two and a half years. On 18 and 19 July 1941, M4050 was fitted with Merlin 61s and reached 433 mph (697 km/h) at 28,500 ft (8,690 m). Multiple ejector exhausts contributed to the increase in speed. On 20 October 1941, W4050 achieved a speed of 437 mph (703 km/h) in level flight. Using two-stage Merlin 77s, it reached 439 mph (706 km/h) in December 1943.[5]

By the end of January 1942, contracts had been awarded for 1,378 Mosquitos of all variants, including 20 T.III trainers and 334 FB.VI bombers. Another 400 were to be built by de Havilland Canada.[31]

Basic design (based on the FB Mk VI)

The Mosquito was a mid-wing (or shoulder-wing) aircraft powered by two Merlin engines.[32] In the most produced variant, the FB 6 (Fighter-bomber Mark 6), two Merlin Mk 23 or Mk 25 engines driving three-bladed hydromatic propellers powered the aircraft.

Construction

The airframe was built mostly from wood. The oval-section fuselage was built in two halves in jigs over a mahogany or basic shape. The join was along the vertical centre line.[33] The spilt construction greatly aided the assembly of the internal equipment as it allowed the technicians easy access.[34] The fuselage construction joints were made from balsa wood and plywood strips. The spruce multi-ply was connected by a V joint, which was balsa made, along with the interior frame. The spruce would be reinforced by plywood strips at the point where the two halves joined to form the V joint. Located on top of the joint the plywood formed the outer skin.[34] During the joining of the two halves ("boxing up"), two laminated wooden clamps would be used in the after portion of the fuselage to act as support.[34][35]

The fuselage was a frameless monocoque shell made of sheets of Ecuadorean balsawood sandwiched between sheets of Canadian birch, but in areas needing extra strength—such as along cut-outs—stronger woods replaced the balsa filler. The plys were formed to shape by band clamps over large concrete moulds, each holding one half of the fuselage, split vertically. While the casein-based glue in the plywood dried, carpenters cut a sawtooth joint into their edges while other workers installed the controls and cabling on the inside wall. When the glue was completely dried, the two halves were glued and screwed together. A covering of doped Madapolam (a fine plain woven cotton) fabric completed the unit. The fuselage could be made in a week by six technicians.[36] The fuselage was separated by seven bulkheads made up of two plywood skins parted by spruce blocks, which formed the basis on each half for the outer shell. The bulkhead was a repeat of the spruce design for the fuselage halves; a balsa sheet sandwich between two plywood sheets/skins. Among the glues used was Casein resin plus many other screws and flanges (made of various woods) which held the structure together. After securing the two halves, the fuselage was covered with fabric and was then doped with cellulose dope which was either sprayed or brushed onto the surface. A coat of silver dope was then applied before exterior camouflage was applied. The underside was cut to allow for wing assembly.[33]

The all-wood wing was installed into the roots by means of four large attachment points. The wing was built as a one-piece structure and was not divided into separate construction sections.[33] It was made up of two main spars, spruce and plywood compression ribs, stringers, and a plywood covering. The outer plywood skin was covered and doped like the fuselage. The engine radiators were fitted in the inner wing, just outboard of the fuselage on either side. These gave less drag.[33] The radiators themselves were split into three sections: an oil cooler section outboard, the middle section forming the coolant radiator and the inboard section serving the cabin heater.[37] The wing contained metal framed and skinned ailerons, but the flaps were made of wood and were hydraulically controlled. The nacelles were mostly wood, but the engine mounts were all metal as were the undercarriage parts (for strength).[33][38] Engine mounts of welded steel tube were added, along with simple landing gear oleos filled with rubber blocks. Wood was used to carry only in-plane loads, with metal fittings used for all triaxially loaded components such as landing gear, engine mounts, control surface mounting brackets, and the wing-to-fuselage junction.[39] The outer leading wing edge had to be brought 22 in. (55 cm) further forward to accommodate this design.[37] The main tail unit was all wood built. The control surfaces, the rudder and elevator were aluminium framed and fabric covered.[33][38] The total weight of metal castings and forgings used in the aircraft was only 280 lb (130 kg).[40]

In November 1944, several crashes occurred in the Far East. At first, it was thought these were as a result of wing structure failures. The casein glue, it was said, cracked when exposed to extreme heat. This caused the upper surfaces to "lift" from the main spar. During the ensuing investigation it was concluded that there were construction defects found at two plants; Hatfield and aircraft built at Standard Motors. The gluing there left “much to be desired”.[41] However, the main reason for the failures, the Air Ministry concluded on 1 January 1945, owed to the weather conditions in Asia, endorsing the view of Major Hereward de Havilland, leading the investigation. To solve the problem, a sheet of plywood was set along the span of the wing to seal the entire length of the skin joint along the main spar.[41]

The casein glue was replaced by "Aerolite", a synthetic urea-formaldehyde adhesive developed by Dr. Norman de Bruyne[42] at Aero Research Limited (ARL), which was better able to resist deterioration in high humidity conditions. The de Havilland company also pioneered the use of radio frequency (RF) heating to accelerate curing of the adhesive.[43]

Fuel, landing gear, electrical power and armament systems

The main landing gear were housed in the nacelles behind the engines. These were raised and lowered hydraulically. The main landing gear shock absorbers were of the rubber in compression type with twin pneumatic brakes for each wheel.[44] The tailplane wheel was retractable.

The fuel systems allowed the light Mosquito frame to obtain a considerable range. There were nine fuel tanks. The two in the outer wing, the "outer tanks", each contained 58 gallons of fuel.[45] The two inner wing fuel tanks, located between the wing root and engine nacelle contained 143 gallons each. The central tank mounted in the fuselage between bulkhead number two and three aft of the cockpit[46], consisted of two 25 gallon fuel tanks. The total fuel load of 452 gallons was initially deemed appropriate for the type.[45] The range could be increased further; the Mk 6 could have larger fuselage tanks, increasing the capacity of the fuselage from 50 to 63 gallons. Two 100 gallon fuel cells were added under the wings to increase the total to 715 gallons. Both the inner wing, and fuselage tanks are listed as the "main tanks".[45] The central and inner wing tanks were pressurised to reduce fuel vaporisation at high altitude, a feature needed in the photographic reconnaissance variants. The pressure venting cock located behind the pilot's seat controlled the pressure valve; as the altitude increased the valve increased the volume applied by a pump. This system was extended to include field modifications of the fuel tank system.[47] The engine oil tanks were in the engine nacelles. Each nacelle contained a 15 gallon oil tank, including a 2.5 gallon air space. The oil tanks themselves had no separate coolant controlling systems. The coolant header tank was in the forward nacelle, behind the propeller. The remaining coolant systems were controlled by the coolant radiators shutters in the forward inner wing compartment, in between the nacelle and the fuselage and behind the main engine cooling radiators which were fitted in the leading edge. Electric-pneumatic operated radiator shutters directed and controlled airflow through the ducts and into the coolant valves to predetermined temperatures.[48]

Electrical power came from a 24 volt DC generator on the starboard (No. 2) engine and an alternator on the port engine which supplied AC power for radios.[44]. The radio shutters, superchargers, gun camera, bomb bay, bomb/rocket release and all the other crew controlled instruments were powered by a 24 volt battery.[48]

The electric generators also powered the fire extinguishers. Located on the starboard side of the cockpit, the switches would operate automatically in the event of a crash. In flight, a warning light button would flash to indicate a fire, should the pilot not already be aware of it. In later models, presumably to save liquids, the fire extinguisher was changed to semi-automatic triggers.[49]

The radio communication devices included VHF and HF communications, GEE navigation, and IFF and G.P devices.

The design of the Mark VI allowed for a provisional long-range fuel tank to increase range for action over enemy territory, for the installation of bomb release equipment specific for depth charge explosives for strikes against enemy shipping, or for the simultaneous use of rocket projectiles and a 100 gallon drop tank under each wing for a 200 gallon supplement to the main fuel cells.[50] The FB 6 had a wingspan of 54 ft 2 in (16.51 m), a length (over guns) of 41 ft 2 in. (12.55 m). It had a maximum speed of 378 mph (608 km/h) at 13,200 ft (4,023 m). Maximum take-off weight was 22,300 lb (10,124 kg) and the range of the aircraft was 1,120 miles (1,802 km) with a service ceiling of 26,000 ft (7,925 m).[51]

Its armament was four Browning .303 machine guns and four 20 mm Hispano cannons for air and soft ground targets. Its bomb load consisted of 2,000 lb (907 kg) of bombs or eight RP-3 unguided rockets.[52]

Pilot's notes and characteristics

Because of its design and light frame, the Mosquito had a low stall speed of 105 knots with undercarriage and flaps raised. When both were lowered, the stall speed decreased to 90 - 100 knots. Stall speed at normal approach angle and conditions was 90 - 95 knots. Warning of the stall was given by buffeting and would occur 10 knots before stall was reached. The conditions and impact of the stall were not severe. The wing did not drop unless the control column was pulled back. The nose drooped gently and recovery was easy.[53] For cruising the maximum speed for obtaining maximum range was 170 knots at 17,000 lb weight.[53] The design was noted for having light and effective control surfaces which allowed for good manoeuvrability. It was noted that the rudder should not be used aggressively at high speeds and the poor aileron control at low speeds when landing and taking off was also a problem for inexperienced crews.[54] For flying at low speeds, the flaps had to be set at 15°, speed reduced to 175 knots (201 mph) and rpm set to 2,650. The speed could be reduced to the acceptable 130 knots for low speed flying.[53]

Variants

Prototypes

Three prototypes were built, each with a different configuration. The first to fly was the bomber prototype W4050 on 25 November 1940, followed by the night fighter model on 15 May 1941 and the photo-reconnaissance model on 10 June 1941.

Photo-reconnaissance aircraft

The photo-reconnaissance prototype became the basis for the Mosquito PR Mk I. The first operational sortie by a Mosquito was made by a PR Mk I on 17 September 1941 (the Bomber Mk IV entered service in May 1942 with No. 105 Squadron). On the very first mission, the unarmed Mosquito PR. I outpaced three Messerschmitt Bf 109s that attempted to engage the aircraft at 23,000 ft (7,000 m).[55] The PR Mk I had a maximum speed of 382 mph (615 km/h), a cruise speed of 255 mph (410 km/h), ceiling of 35,000 ft (10,670m), a range of 2,180 nm (3,510 km), and a climb rate of 2,850 feet per minute (869m).[56]

The Mosquito PR Mk IV was 27 Mosquito B. Mk IV bombers, converted into two-seat photo-reconnaissance aircraft. The type first flew in April 1942.[57] The Mosquito PR Mk VIII was the next photo-reconnaissance version. It was to fill as an interim solution until Mk PR IX and XVI models were available in large numbers. The VIII was based on the IV but it was powered by two Rolls-Royce Merlin 61 engines in place of Merlin 21/22s. It first flew on 20 October 1941. The four built were converted from B. IVs.[57] The PR Mk VIII had a maximum speed of 436 mph (700 km/h), a cruise speed of 258 mph (415 km/h), ceiling of 38,000 ft (11,580 m), a range of 2,550 nm (4,100 km), and a climb rate of 2,500 feet per minute (762m).[56]

The Mosquito PR Mk IX was another unpressurized version without any armament. It first flew on 24 March 1943; 54 were built in total. It was based on the Mosquito B.Mk IX bomber aircraft. Powered by two 1,680 hp (1,253 kW) Merlin 72/73 or 76/77 engines. It could carry either two 50 gallon (230 litre), two 100 gallon (455 litre) or two 200 gallon (910 litre) droppable fuel tanks. In total 90 were built.[57]

The Mosquito PR Mk XVI had a pressurised cockpit and three additional fuel tanks in the bomb bay. It was powered by two Rolls-Royce Merlin 72/73 or 76/77 piston engines. A total of 435 of the PR Mk XVI were built.[57] The PR Mk XVI had a maximum speed of 415 mph (668 km/h), a cruise speed of 250 mph (402 km/h), ceiling of 38,500 ft (11,730 m), a range of 2,450 nm (3,942 km), and a climb rate of 2,900 feet per minute (884 m).[56]

The Mosquito PR Mk 32 was a long-range, high-altitude pressurized photo-reconnaissance version. It was powered by a pair of two-stage supercharged 1,960 hp (1,260 kW) Rolls-Royce Merlin 113 and Merlin 114 piston engines. The Merlin 113 on the starboard side and the Merlin 114 on the port. First flown in August 1944, only five were built and all were conversions from PR. XVIs.[58] The Mosquito PR Mk 34 and PR Mk 34A was a very long-range unarmed high altitude photo-reconnaissance version. The fuel tank and cockpit protection armour were removed. Addition fuel was carried in a bulged bomb-bay: 1,192 gallons which was the equivalent of 5,419 miles. A further two 200 gallon (910 litre) drop tanks under the outer wings gave a range of 3,600 miles (5,800 km) cruising at 300 mph (480 km/h). Powered by two 1,690 hp (1,259 kW) Merlin 114s first used in the PR. 32. The port Merlin 114 drove a Marshal cabin supercharger. 181 were built including 50 built by Percival Aircraft Company at Luton.[58] The PR.34's maximum speed (TAS) was 335 mph at sea level, 405 mph at 17,000 feet and 425 mph at 30,000 feet.[59] All PR. 34s were installed with four split F.52 vertical cameras, two forward, two aft of the fuselage tank and one F.24 oblique camera. Sometimes a K.17 camera was used for air surveys. In August 1945 the PR.34A was the final photo-reconnaissance variant with one Merlin 113A and 114A each delivering 1,710 hp (1,274 kW).[60]

Bombers

On 21 June 1941 the Air Ministry ordered that the last 10 Mosquitos, ordered as PR aircraft, should be converted to bomber use. These 10 machines were part of the original 1 March 1940 production order. These became the B.IV Series I. Aircraft W4072 was to be the prototype. It flew for the first time on 8 September 1941. The 50 B.IV series II bombers differed from the series I in having a larger bomb bay to increase the payload to four 500 lb bombs instead of four 250 lb (115 kg) bombs of Series I. This was made possible by shortening the stabilizer of the 500 lb (230 kg) bomb so that these four larger weapons could be carried.[61]

The bomber prototype led to the B Mk IV, of which 273 were built.[62] The B Mk IV could accommodate four 500 lb bombs, or a 2,000 lb (227 kg) total load in the bomb bay.[62] Some of these variants were later converted for special operations with the Highball anti-shipping weapon. A B.IV was used a trials aircraft for the bomb. In RAF Bomber Command 54 B.IVs were modified to have bulged bomb bays to carry a 4,000 lb (1,812 kg) High explosive bomb to operate as a light night-striking force.[62] The B.Mk. IV had a maximum speed of 380 mph (611 km/h), a cruising speed of 265 mph (426 km/h), ceiling of 34,000 ft (10,360 m), a range of 2,040 nm (3,280 km), and a climb rate of 2,500 feet per minute (762 m).[56]

Other bomber variants of the Mosquito included the Merlin 21 powered B Mk. V high-altitude version. Trials with this configuration were made with W4057 which had the wings strengthened and an addition of two fuel tanks. Alternately, two 500 lb (227 kg) bombs. This design was not produced in Britain, but formed the basic design of the Canadian-built B.VII. Only the W4057 was built in prototype form.[63] The Merlin 31 powered B.Mk.VII was built by de Havilland Canada. It was based on the B.V and first flown on 24 September 1942. It only saw service in Canada and only 25 were built. Six were handed over to the United States Army Air Force. B.Mk.IX (54 built) was powered by either the Merlin 72,73, 76 or 77. The two-stage Merlin variant was based on the PR.IX. The prototype was converted from a PR.VIII. Prototype DK 324 was first flown on 24 March 1943.[64] The B.Mk. IX had a maximum speed of 408 mph (656 km/h), a cruising speed of 250 mph (402 km/h), ceiling of 36,000 ft (10,970 m), a range of 2,450 nm (3,940 km), and a climb rate of 2,850 feet per minute (869 m). The IX could carry a maximum load of 2-4,000 lb (910-1,810 kg) of bombs.[56] A Mosquito B.IX holds the record for the most combat missions flown by an Allied bomber in the Second World War. LR503, known as "F for Freddie" because of its squadron code letters, GB*F, first served with 109 and subsequently 105 Squadron of the RAF. It flew 213 sorties during the war, only to crash at Calgary airport during the 8th Victory Loan Bond Drive on 10 May 1945, two days after Victory in Europe Day, killing both the pilot, Flt. Lt. Maurice Briggs, DSO, DFC, DFM and navigator Fl. Off. John Baker, DFC and Bar.[65]

The B.Mk.XVI was powered by the same variations as the IX. The two-stage powerplants were added along with a pressurised cabin. DZ540 first flew on the 1 January 1944. The prototype was converted from a IV (402 built). The nest variant, the B.Mk.XX, was powered by Packard Merlins 31 and 33s. It was the Canadian version of the IV. Altogether, 245 were built. B.Mk.35s were powered by Merlin 113 and 114As. Some were converted to TT.35s (Target Tugs) and others were used as PR.35s (photo reconnaissance).[64] The B.Mk. XVI had a maximum speed of 408 mph (656 km/h), a cruising speed of 245 mph (394 km/h), ceiling of 37,000 ft (11,280 m), a range of 1,485 nm (2,390 km), and a climb rate of 2,800 feet per minute (853 m). The type could carry 4,000 lb (1,810 kg) of bombs.[56] The B.35 had a maximum speed of 422 mph (679 km/h), a cruising speed of 276 mph (444 km/h), ceiling of 42,000 ft (12,800 m), a range of 1,750 nm (2,820 km), and a climb rate of 2,700 feet per minute (823 m).[66]

Fighter aircraft

Developed during 1940, the Mosquito F Mk II was developed and the first prototype was completed on 15 May 1941. These aircraft were fitted with four 20 mm (.79 in) Hispano cannon in the fuselage belly and four .303 in (7.7 mm) Browning machine guns mounted in the nose. This fit required the movement of the crew ingress/egress door from the bottom to the right side of the nose. The aircraft also featured a modified windscreen, with flat bulletproof panels in front.[67]

The aircraft was made largely out of wood, the majority of it being plywood. Notable features were the leading edge radiators and the use of compression rubber blocks in the undercarriage legs. The type was also fitted with a gun camera in a compartment above the weapons themselves in the nose. The aircraft was also fitted with exhaust flame dampers to handle the Merlin XX's fumes. The machine had an aspect ratio of seven.[68]

Night fighter aircraft

The first production night fighter Mosquitos were designated Mosquito NF Mk II. A total of 466 were built with the first entering service with No. 157 Squadron in January 1942, replacing the Douglas Havoc. These aircraft were similar to the F Mk II, but were fitted with the AI Mk IV metric wavelength radar. The herring-bone transmitting antenna was mounted on the nose and the dipole receiving antennae were carried under the outer wings.[69] A number of NF IIs had their radar equipment removed and additional fuel tanks installed for use as night intruders. These aircraft, designated NF II (Special) were first used by 23 Squadron in operations over Europe in 1942.[70] No. 23 Squadron was then deployed to Malta on 20 December 1942, and operated against targets in Italy.[71]

Ninety-seven NF Mk IIs were upgraded with centrimetric AI Mk VIII radar and these were designated Mosquito NF.Mk XII. The Mosquito NF Mk XIII, of which 270 were built, was the production equivalent of the Mk XII conversions. The centimetric radar sets were mounted in a solid "thimble" (Mk XII / XIII) or "bull nose" (Mk XVII / XIX) radome, which required the machine guns to be dispensed with. The other night fighter variants were the Mk XV, Mk XVII (converted Mk IIs), Mk XIX and Mk 30. The last three marks mounted the U.S.-built AI Mk X radar.

- Mosquito NF Mk X: Unbuilt night fighter version.

- Mosquito NF Mk XI: Unbuilt night fighter version.

- Mosquito NF Mk XIV: Unbuilt night fighter version.

- Mosquito NF Mk XV: This designation was given to five Mosquito B.Mk IV bombers, which were converted into two-seat high-altitude night fighters.

- Mosquito NF Mk XVII: Designation for 99 NF.II conversions, with single-stage Merlin 21, 22, or 23 engines, but British AI.X (US SCR-720) radar.

- Mosquito NF Mk XIX: Improved version of the Mosquito NF XIII night fighter aircraft. It could be fitted with American or British AI radars; 220 built.

- Mosquito NF Mk 30: High-altitude night fighter version. Powered by two 1,710 hp (1,275 kW) Roll-Royce Merlin 76 piston engines, enabling a 424 mph (682 km/h) top speed at 26,500 ft (8,100 m).[72] It also carried early electronic countermeasures equipment. 526 built.

- Mosquito NF Mk 31: Unbuilt night fighter version.

After the war, two more night fighter versions were developed, the NF Mk 36 and the NF Mk 38.

- Mosquito NF Mk 36: Similar to the Mosquito NF.Mk 30, but fitted with the American-built AI.Mk X radar. Powered by two 1,690 hp (1,260 kW) Roll-Royce Merlin 113/114 piston engines; 266 built. Max level speeds (TAS) with flame dampers fitted were 305 mph at sea level, 380 mph at 17,000 feet, and 405 mph at 30,000 feet.[59]

- Mosquito NF Mk 38: Similar to the Mosquito NF.Mk 30, but fitted with the British-built AI Mk IX radar. 50 built. Type had a VNE of 370 knots (425 mph) without under wing add-ons and within the altitude of seal level to 10,000 feet. From 10,000 to 15,000 feet the fell to 348 knots (400 mph). As the height increased other recorded speeds are as follows; 15,000 to 20,000 feet speed was 320 knots (368 mph); 20,000 to 25,000 feet, speed was 295 knots (339 mph); 25,000 to 30,000 feet, 260 knots (299 mph); 30,000 to 35,000 feet, speed was 235 knots (270 mph). With two added 100 gallon fuel tanks this performance falls; between sea level and 15,000 feet 330 knots (379 mph); between 15,000 to 20,000 feet it drops to 320 knots (368 mph); 20,000 to 25,000 feet, speed was 295 knots (339 mph); 25,000 to 30,000 feet, 260 knots (299 mph); 30,000 to 35,000 feet, speed was 235 knots (270 mph). Little difference is noted in speed above 15,000 feet.[73]

Mosquito night intruders of No. 100 Group RAF, Bomber Command, were also fitted with a device called "Serrate" to allow them to track down German night fighters from their Lichtenstein B/C and SN-2 radar emissions, as well as a device named "Perfectos" that tracked German IFF signals.

Fighter-bomber aircraft

The most numerous Mosquito variant was the FB Mk VI fighter-bomber of which 2,298 were built, some one-third of Mosquito production.[57] The protoype was converted from a B.VI first flew in February 1943.[57]

The FB Mk VI was powered by two 1,460 hp (1,088 kW) Merlin 21s or 1,635 hp (1,218 kW) Merlin 25s.[57] It first flew on 1 June 1942. Some 19 that were built by Airspeed Ltd were eventually modified to be completed as FB.XVIIIs. Two were converted to TR.33 maritime assault prototypes. The variant was generally armed with four 20 mm cannon and four .303 (7.7 mm) machine guns for hitting soft ground targets. The main hitting power came from the two 250 lb (115 kg) bombs enclosed in the bomb bay plus more and was later plus two RP-3 "60 lb" rockets to carry out anti-shipping strikes. Other variations of armament fixtures could have entailed eight 60 lb (27 kg) rockets in place of any other internal load. Later the main bomb load was upgraded to two 500 lb (230 kg) bombs. Alternatively, a third option could have been an aerial mine or depth charge for attacking German submarines.[57]

The FB Mk VI proved durable in dogfights with single-engine fighter aircraft. Retaining the forward firing armament Mosquito FB Mk VIs of No. 143 Squadron RAF were engaged by 30 Focke-Wulf Fw 190s from Jagdgeschwader 5 on 15 January 1945. In the ensuing battle the Mosquitos lost five aircraft but shot down five Fw 190s in return as well as sinking an armed trawler and two merchant ships.[74]

All-out level speed is often given as 368 mph, however this speed applies to aircraft fitted with saxophone exhausts. The test aircraft (HJ679) fitted with stub exhausts was found to be performing below expectations. It was returned to de Havilland at Hatfield where it was serviced. Its top speed was then tested and found to be 384 mph, in line with expectations.[75]

Other fighter-bomber variants were the Mosquito FB Mk XVIII (sometimes known as the Tsetse) of which 18 were built and a total of 27 were made by converting Mk VIs. These were fitted with a Molins "6-pounder Class M" cannon, a modification of the QF 6-pounder (57 mm) anti-tank gun weighing 1,580 lb (716 kg) fitted with an auto-loader to allow both semi- or fully-automatic fire, in the nose, along with two .303 in (7.7 mm) sighting machine guns. The cannon was later deleted.[58] The Air Ministry initially suspected that this variant would not work, but mock tests proved otherwise. Although the gun provided the Mosquito with yet more anti-shipping firepower for use against U-boats it required a steady, and hence vulnerable, approach-run to aim and fire the gun. In comparison, rockets were more effective, especially because the 6-pounder was a significant weight penalty. The gun carried 24 rounds for the 6 pounder which had a muzzle velocity of 2,950 ft/s (900 m/s).[58] The guns had an excellent range, some 1,800 - 1,500 yards (1,650 - 1,370 m). The gun was sensitive to sidewards movement and an attack required a dive from 5,000 ft (1,520 m) at a 30° angle with the Turn and bank indicator on centre. A move during the dive could jam the cannon.[76] The prototype was converted from a FB.VI and was first flown on 8 June 1943.[58]

The effect of the new weapon was demonstrated on 10 March 1944 when four Mk VIs escorting XVIIIs from 248 Squadron engaged a German convoy of one U-Boat and four destroyers, protected by 10 Ju 88s. Three of the Ju 88s were shot down. Pilot Tony Phillips destroyed one Ju 88 with four shells, one of which tore the engine off the Ju 88. The U-Boat was damaged. On 25 March, U-976 was sunk by Molins-equipped Mosquitos.[77] On 10 June, U-821 was abandoned in the face of intense air attack from No. 248 Squadron, and was later sunk by a Liberator of No. 206 Squadron.[78] On 5 April 1945 Molins Mosquitos again demonstrated their value and attacked five German surface ships in the Kattegat and set all of them on fire and sinking.[79][80] The Sperrbrecher was lost with all hands, with some 200 bodies being recovered by Swedish vessels.[79] Some 900 German soldiers died in total.[79] On 9 April German U-Boats U-804, U-843 and U-1065 were spotted in formation heading for Norway. All were sunk.[79][81] U-251 and U-2359 followed on the 19 April and 2 May 1945.[82]

Despite the preference for rockets, a further development of the idea was carried out using the even larger 32-pounder, a gun based on the QF 3.7 inch AA gun designed for tank use, the airborne version using a novel form of muzzle brake. Developed to prove the feasibility of using such a large weapon in the Mosquito, this installation was not completed until after the war when it was flown and fired in a single aircraft without problems before being scrapped. The FB Mk 26 and FB Mk 40, based on the Mk VI, were built in Canada and Australia and were powered by later versions of the Packard-built Merlin engines. The FB.26 was the Canadian variant version of the VI and improved from the FB.21. Two 1,620 hp (1,207 kW) single stage Packard built Merlin 225s. Some 300 were built and another 37 converted to T.29 standard.[58] 212 FB.40s were built by versions of FB.VI were produced by de Havilland Australia. Six were converted to PR.40; 28 to PR.41s one to FB.42 and 22 to T.43s tactical assault aircraft. Most units were powered by Packard-built Merlin 31 or 33s.[60]

All the fighter variants shared a number of common features. They had a flat, single-piece armoured windscreen and the pilot was provided with a fighter-style control stick rather than a wheel. The guns in the nose also meant that the bomber variants' entry hatch in the nose had to be relocated to a door on the starboard side, forward of the leading edge.

Training aircraft

The Mosquito was also built as a trainer.

- Mosquito T Mk III : Two-seat training version. Powered by two Rolls-Royce Merlin 21 piston engines. A total of 348 of the T Mk III were built for the RAF and Fleet Air Arm. de Havilland Australia built 11 T Mk 43 trainers, similar to the Mk III.

Torpedo reconnaissance fighter aircraft

To meet specification N.15/44 for Royal Navy use, de Havilland produced a carrier-borne variant. This resulted in 50 Sea Mosquito TR Mk 33s which featured folding wings, a thimble nose radome and fuselage hardpoints for mounting aerial torpedoes. These were followed by 14 Sea Mosquito TR Mk 37s, which differed in having ASV Mk. XIII radar instead of the TR.33's AN/APS-6.

Target tug aircraft

The Royal Navy also operated the Mosquito TT Mk 39 for target towing. A number of B Mk XVIs bombers were converted into TT.Mk 39 target tug aircraft. The RAF's target tug version was the Mosquito TT Mk 35 which were the last aircraft to remain in operational service, finally being retired in 1956.

Canadian-built aircraft

A total of 1,133[83] (to 1945) Mosquitos were built by De Havilland Canada at Downsview Airfield in Downsview Ontario (now Downsview Park in Toronto Ontario).

- Mosquito B Mk VII : Canadian version based on the Mosquito B Mk V bomber aircraft. Powered by two 1,418 hp (1,057 kW) Packard Merlin 31 piston engines; 25 built.

- Mosquito B Mk XX : Canadian version of the Mosquito B Mk IV bomber aircraft; 145 built, of which 40 were converted into F-8 photo-reconnaissance aircraft for the USAAF.

- Mosquito FB Mk 21 : Canadian version of the Mosquito FB Mk VI fighter-bomber aircraft. Powered by two 1,460 hp (1,089 kW) Rolls-Royce Merlin 31 piston engines, three built.

- Mosquito T Mk 22 : Canadian version of the Mosquito T Mk III training aircraft.

- Mosquito B Mk 23 : Unused designation for a bomber variant.

- Mosquito FB Mk 24 : Canadian fighter-bomber version. Powered by two 1,620 hp (1,208 kW) Rolls-Royce Merlin 301 piston engines; two built.

- Mosquito B Mk 25 : Improved version of the Mosquito B Mk XX Bomber aircraft. Powered by two 1,620 hp (1,208 kW) Packard Merlin 225 piston engines; 400 built.

- Mosquito FB Mk 26 : Improved version of the Mosquito FB Mk 21 fighter-bomber aircraft. Powered by two 1,620 hp (1,208 kW) Packard Merlin 225 piston engines; 338 built.

- Mosquito T Mk 27 : Canadian-built training aircraft.

- Mosquito T Mk 29 : A number of FB Mk 26 fighters were converted into T Mk 29 trainers.

Australian-built aircraft

- Mosquito FB Mk 40 : Two-seat fighter-bomber version for the RAAF. Powered by two 1,460 hp (1,089 kW) Roll-Royce Merlin 31 piston engines. A total of 178 built in Australia.

- Mosquito PR Mk 40 : This designation was given to six FB Mk 40s, which were converted into photo-reconnaissance aircraft.

- Mosquito FB Mk 41 : Two-seat fighter-bomber version for the RAAF. A total of 11 were built in Australia.

- Mosquito PR Mk 41 : Two-seat photo-survey version for the RAAF. A total of 17 were built in Australia.

- Mosquito FB Mk 42 : Two-seat fighter-bomber version. Powered by two Rolls-Royce Merlin 69 piston engines. One FB Mk 40 aircraft was converted into a Mosquito FB Mk 42.

- Mosquito T Mk 43 : Two-seat training version for the RAAF. A total of 11 FB Mk 40s were converted into Mosquito T Mk 43s.

Production

In England, fuselage shells were mainly made by the furniture companies Ronson, E. Gomme, Parker Knoll and Styles & Mealing. The specialized wood veneer used in the construction of the Mosquito was made by Roddis Manufacturing in Marshfield, Wisconsin, United States. Hamilton Roddis had teams of dexterous young women ironing the (unusually thin) strong wood veneer product before shipping to the UK.[84] Wing spars were made by J.B. Heath and Dancer & Hearne. Many of the other parts, including flaps, flap shrouds, fins, leading edge assemblies and bomb doors were also produced in High Wycombe, Buckinghamshire, which was well suited to these tasks because of a well established furniture-manufacturing industry. Dancer & Hearne processed much of the wood from start to finish, receiving timber and transforming it into finished wing spars at their High Wycombe factory.

| Producer and site | Number built |

|---|---|

| de Havilland Hatfield, Hertfordshire | 3,326 |

| de Havilland Leavesden, Hertfordshire | 1,476 |

| Standard Motor Company, Coventry | 1,066 |

| Percival Aircraft Company, Luton | 245 |

| Airspeed Aircraft, Portsmouth | 122 |

| de Havilland Hawarden[85], Chester | 96 |

| de Havilland Canada, Toronto | 1,076 |

| de Havilland Australia, Sydney | 212 |

About 5,000 of the 7,781 Mosquitos made contained parts made in High Wycombe.[84] In Canada, fuselages were built in the Oshawa, Ontario plant of General Motors of Canada Limited. These were shipped to De Havilland of Canada in Toronto for mating to fuselages and completion. As a secondary manufacturer, de Havilland Australia started construction in Sydney. These production lines added 1,076 from Canada and 212 from Australia.

Total Mosquito production was 7,781 of which 6,710 were built during the war. The ferry operation of the Mosquito from Canada to the war front was problematic, as a small fraction of the aircraft would mysteriously disappear over the mid-Atlantic. The theory of "auto-explosion" was offered, and, although a concentrated effort at de Havilland Canada to address production problems with engine and oil systems reduced the number of aircraft lost, it was unclear as to the actual cause of the losses. The company introduced an additional five hours flight testing to "clear" production aircraft before the ferry flight. By the end of the war, nearly 500 Mosquito bombers and fighter-bombers were delivered successfully by the Canadian operation.[86]

In total, both during the war and post war, de Havilland exported 46 FB.V1 and 29 PR.XVI to Australia, two FB.VI and 18 NF.30s to Belgium, approximately 205 FB.26, T.29, T.27s to Nationalist China, 19 FB.VIs to Czechoslovakia in 1948, 6 FB. VIs to Dominica, a few B.IVs, 57 FB.VI, 29 PR.XVIs and 23 NF.XXX to France. Some T.IIIs were exported to Israel along with 60 FB.VIs, and at least 5 PR.XVIs and 14 naval versions. Four T.IIIs, 76 FB.VIs, one FB.40 and four T.43s were exported to New Zealand. Three T.IIIs were exported to Norway, and 18 FB.VIs which were later converted to night fighter standard. South Africa received two F.II and 14 PR.XVI/XIs and Sweden received 46 NF.XIXs. Turkey received 96 FB.VIs and several T.IIIs, and Yugoslavia had 60 NF.38s, 80 FB.VIs and three T.IIIs delivered.[2]

Operational history

The de Havilland Mosquito operated in many roles during the Second World War. Mosquito-equipped squadrons were asked to perform medium bomber, reconnaissance, tactical strike, anti-submarine warfare and shipping attack and Night fighter duties, both defensive and offensive, until the end of the war.[87] The Mosquito was first announced publicly on 26 September 1942 after the Oslo Mosquito raid of 25 September.

Mosquitos were widely used by the RAF Pathfinder Force, which marked targets for night-time strategic bombing. Despite an initially high loss rate, the Mosquito ended the war with the lowest losses of any aircraft in RAF Bomber Command service. Post war, the RAF found that when finally applied to bombing, in terms of useful damage done, the Mosquito had proved 4.95 times cheaper than the Lancaster[88]

Special Luftwaffe units (Jagdgeschwader 25 and Jagdgeschwader 50) were formed to combat the Mosquito attacks, though they were rather unsuccessful. Hermann Göring ordered the formation of the units in response to the "political humiliation" in April 1943.[89] JG 25 and JG 50 were to be commanded by Oberstleutnant Herbert Ihlefeld and Major Hermann Graf. The units were "little more than glorified squadrons and achieved little against the elusive RAF aircraft".[89] To cover the Luftwaffe's impotence the units were given great propaganda value by German propaganda. Walter Grabmann stated that the units were not worth the expenditure in light of the results they obtained.[89]

The Mosquito famously annoyed the Commander in Chief of the Luftwaffe, Reichsmarschall Hermann Göring, when, on 20 January 1943, the 10th anniversary of the Nazis' seizure of power, a Mosquito attack knocked out the main Berlin broadcasting station, putting his speech off air. Göring complained about the high speed of the aircraft and its wooden structure, built by a nation he perceived to have large amounts of metal reserves, while the Germans had shortages of such materials and could not produce such a design.[90]

The Mosquito operated in both defensive and offensive operations for the duration of the war. The Mosquito flew its last official European war mission on 21 May 1945, when Mosquitos of 143 Squadron and 248 Squadron RAF were ordered to continue to hunt German submarines that might be tempted to continue the fight. Only passive E-Boats were encountered.[91]

Some of the most successful RAF pilots flew the Mosquito. Night fighter pilots Wing Commander Branse Burbridge claimed 21 kills; Bob Braham claimed around a third of his 29 kills in a Mosquito. John Cunningham claimed 19 of his 20 victories at night in his Mosquito "Cat's Eyes".

One Mosquito is listed as belonging to German secret operations unit Kampfgeschwader 200, which tested, evaluated and sometimes clandestinely operated captured enemy aircraft during the war. The aircraft was listed on the order of battle of Versuchsverband OKL's, 2 Staffel, Stab Gruppe on 10 November and 31 December 1944. However, on both lists, the Mosquito is listed as unserviceable.[92]

Operators

Survivors

There are approximately 30 surviving examples around the world with several under restoration. In 1963 aircraft collector Lynn Garrison purchased a B.35 (RS700)(CF-HMS) from Spartan Air Services for display in Calgary, Alberta. As of July, 2010 it is being restored by the Calgary Mosquito Society. The largest collection of Mosquitos is at the de Havilland Aircraft Heritage Centre, which owns three aircraft. Three are currently under restoration to fly including one owned by Jerry Yagen, crafted by Glynn Powell in Auckland, New Zealand.[93]

Specifications

DH.98 Mosquito F. Mk II

Data from Mosquito[94] and Mosquito Performance trials[95]

General characteristics

- Crew: 2: pilot, navigator/radar operator

- Length: 41 ft 2 in (13.57 m)

- Wingspan: 54 ft 2 in (16.52 m)

- Height: 17 ft 5 in (5.3 m)

- Wing area: 454 ft² (42.18 m²)

- Empty weight: 13,356 lb (6,058 kg)

- Loaded weight: 17,700 lb (8,028 kg)

- Max takeoff weight: 18,649 lb (8,549 kg)

- Powerplant: 2× Rolls-Royce Merlin 21/21 or 23/23 (left/right) liquid-cooled V12 engine, 1,480 hp (21 & 23) (1,103 kW) each

Performance

- Maximum speed: 318 kn (366 mph, 610 km/h) at 21,400 ft (8,500 m)[96]

- Range: 782 nmi (900 mi, 1,500 km) with 410 gal (1,864 litre) fuel load at 20,000 ft (6,100 m)

- Service ceiling: 29,000 ft (8,839 m)

- Rate of climb: 1,740 ft/min (8.8 m/s)

- Wing loading: 39.9 lb/ft² (195 kg/m²)

- Power/mass: 0.189 hp/lb (311 W/kg)

Armament

- Guns: 4 × 20 mm (.79 in) Hispano Mk II cannon (fuselage) and 4 × .303 in (7.7 mm) Browning machine guns (nose)

Avionics

- AI Mk IV or Mk V radar (NF variants)

DH.98 Mosquito B Mk XVI

Data from Jane's Fighting Aircraft of World War II[94] and World War II Warbirds[97]

General characteristics

- Crew: 2: pilot, bombardier/navigator

- Length: 44 ft 6 in (13.57 m)

- Wingspan: 54 ft 2 in (16.52 m)

- Height: 17 ft 5 in (5.3 m)

- Wing area: 454 ft² (42.18 m²)

- Empty weight: 14,300 lb (6,490 kg)

- Loaded weight: 18,100 lb (8,210 kg)

- Max takeoff weight: 25,000 lb (11,000 kg)

- Powerplant: 2× Rolls-Royce Merlin 76/77 (left/right) liquid-cooled V12 engine, 1,710 hp (1,280 kW) each

Performance

- Maximum speed: 361 kn (415 mph, 668 km/h) at 28,000 ft (8,500 m)

- Range: 1,300 nmi (1,500 mi, 2,400 km) with full weapons load

- Service ceiling: 37,000 ft (11,000 m)

- Rate of climb: 2,850 ft/min (14.5 m/s)

- Wing loading: 39.9 lb/ft² (195 kg/m²)

- Power/mass: 0.189 hp/lb (311 W/kg)

Armament

- Bombs: 4,000 lb (1 800 kg)

Avionics

- GEE radio-navigation

Notable appearances in media

See also

- Oslo Mosquito raid

Related development

- de Havilland Hornet/Sea Hornet

Comparable aircraft

- Bristol Beaufighter

- Junkers Ju 88

- Messerschmitt Me 410

- Heinkel He 219

- Focke-Wulf Ta 154

- P-61 Black Widow

- Petlyakov Pe-2

- FMA I.Ae. 24 Calquin

- A-26 Invader

Related lists

- List of aircraft of the RAF

- List of bomber aircraft

References

- Notes

- ↑ 1.0 1.1 Bowman 2005, p. 8.

- ↑ 2.0 2.1 2.2 Bowman 2005, p. 163.

- ↑ "deHavilland DH 98 Mosquito." warbirdalley.com. Retrieved: 10 August 2009.

- ↑ 4.0 4.1 4.2 Bellows, Alan. on "The Timber Terror." DamnInteresting.com, 11 November 2006. Retrieved: 10 August 2009.

- ↑ 5.0 5.1 5.2 5.3 5.4 5.5 Bowman 2005, p. 21.

- ↑ Hastings 1979, p. 240.

- ↑ "Pathfinder Aircraft: The Mosquito." RAF Pathfinder Command. Retrieved: 28 March 2010.

- ↑ " Hermann Göring im Gespräch mit Generalfeldmarschall Milch im März 1943 zur Mosquito (Original German)." luftkrieg-ederbergland.de. Retrieved: 28 March 2010.

- ↑ Bowman 2005, p. 9.

- ↑ 10.0 10.1 10.2 10.3 10.4 Bowman 2005, p. 10.

- ↑ 11.0 11.1 Jackson 2003, p. 5.

- ↑ Rickard, J. "De Havilland Mosquito: Introduction and Initial Development." historyofwar.org, 15 April 2007. Retrieved: 10 August 2009.

- ↑ Sharp and Bowyer 1971, p. 31.

- ↑ Buttler 2004, pp. 76–77.

- ↑ "Britain's Armstrong Whitworth Albemarle Transport - World War II Vehicles, Tanks, and Airplanes." wwiivehicles.com. Retrieved: 18 February 2010.

- ↑ Buttler 2004, pp. 74, 77.

- ↑ Batchelor and Lowe 2008, p. 5.

- ↑ 18.0 18.1 18.2 18.3 Batchelor and Lowe 2008, p. 6.

- ↑ Bishop 1995

- ↑ Bishop 1995,

- ↑ 21.0 21.1 21.2 21.3 21.4 21.5 21.6 21.7 Bowman 2005, p. 11.

- ↑ 22.0 22.1 Buttler 2004, p. 78.

- ↑ Buttler 2004, p. 79.

- ↑ 24.0 24.1 24.2 24.3 Bowman 2005, p. 12.

- ↑ Jackson 2003, p. 6.

- ↑ Jackson 2003, p. 7.

- ↑ "De Havilland Mosquito - Great Britain." Aviation History Online Museum , 7 August 2009. Retrieved: 10 August 2009.

- ↑ 28.0 28.1 Bowman 2005, p. 18.

- ↑ 29.0 29.1 29.2 Bowman 2005, p. 19.

- ↑ 30.0 30.1 30.2 Bowman 2005, p. 20.

- ↑ Bowman 2005, p. 24.

- ↑ Air Ministry 1945, p. 13. (NF 38 notes)

- ↑ 33.0 33.1 33.2 33.3 33.4 33.5 Batchelor and Lowe 2008, p. 7.

- ↑ 34.0 34.1 34.2 Bowman 2005, p. 15.

- ↑ Jackson 2003, p. 8.

- ↑ Jackson 2003, pp. 8–9.

- ↑ 37.0 37.1 Jackson 2003, p. 87.

- ↑ 38.0 38.1 Jackson 2003, p. 9.

- ↑ Miracle and Donaldson 2001, p. 870.

- ↑ "History of the de Havilland Mosquito." RAAF Museum Point Cook, 2007. Retrieved: 13 August 2009.

- ↑ 41.0 41.1 Bowman 2005, pp. 15–16.

- ↑ "The De Bruyne Medal." Society for Adhesion and Adhesives .

- ↑ Mujumdar 1992, p. 131.

- ↑ 44.0 44.1 Bishop 1995 Appendix 1

- ↑ 45.0 45.1 45.2 Air Ministry 1945, p. 11. (FB 6 notes).

- ↑ Bowman 2005, p. 22.

- ↑ Air Ministry 1945, pp. 13–14. (FB 6 Notes)

- ↑ 48.0 48.1 Air Ministry 1945, p. 14. (FB 6 notes).

- ↑ Air Ministry 1945, p. 44. (FB 6 notes).

- ↑ Air Ministry 1945, p. 11. (FB 6 notes)

- ↑ Batchelor and Lowe 2008, pp. 16–17.

- ↑ Batchelor and Lowe 2008, p. 17.

- ↑ 53.0 53.1 53.2 Air Ministry 1945, p. 29. (FB 6 notes).

- ↑ Air Ministry 1945, pp. 28–29. (FB 6 notes)

- ↑ Bowman 2005, p. 27.

- ↑ 56.0 56.1 56.2 56.3 56.4 56.5 Bowman 2005, p. 25.

- ↑ 57.0 57.1 57.2 57.3 57.4 57.5 57.6 57.7 Bowman 2005, p. 164.

- ↑ 58.0 58.1 58.2 58.3 58.4 58.5 Bowman 2005, p. 165.

- ↑ 59.0 59.1 "The latest Mosquitoes." Flight, 28 February 1946. via flightglobal.com. Retrieved: 17 August 2010.

- ↑ 60.0 60.1 Bowman 2005, p. 166.

- ↑ Bowman 2005, pp. 22–23.

- ↑ 62.0 62.1 62.2 Jackson 2003, p. 15.

- ↑ Jackson 2003, p. 16.

- ↑ 64.0 64.1 Jackson 2003, p. 17.

- ↑ Bowman 2005, p. 70.

- ↑ Bowman 2005, p. 26.

- ↑ Scutts 1993, pp. 4–5.

- ↑ Bowman 2005, p. 13.

- ↑ Scutts 1993, p. 7.

- ↑ Sharp and Bowyer 1971, pp. 338–339.

- ↑ Scutts 1993, p. 8.

- ↑ Sharp and Bowyer 1971, p. 434.

- ↑ Air Ministry 1945, pp. 38–39. (NF 38 Notes)

- ↑ Bowman 2005, p. 112.

- ↑ [http://www.wwiiaircraftperformance.org/mosquito/hj679-dh.pdf "Mosquito FB. Mk. VI HJ.679 - Brief performance trials, A. & A.E.E. Boscombe Down "] via wwiiaircraftperformance.org. Retrieved: 17 August 2010.

- ↑ Bowman 2005, p. 105.

- ↑ Bowman 2005, pp. 106–106.

- ↑ Bowman 2005, p. 108.

- ↑ 79.0 79.1 79.2 79.3 Bowman 2005, p. 115.

- ↑ Bowman 1997, p. 77.

- ↑ Bowman 1997, p. 78.

- ↑ Bowman 2005, pp. 117, 119.

- ↑ Banigan, Richard. "Mosquito Aircraft Production at Downview." virtualmuseum.ca. Retrieved: 17 August 2010.

- ↑ 84.0 84.1 Cole 2001

- ↑ A former Vickers-Armstrong shadow factory

- ↑ Hotson 1983, pp. 77–87.

- ↑ Bowman 2005, p. 7.

- ↑ AVIA 46/116 De Haviland Mosquito papers, 1939-1945.

- ↑ 89.0 89.1 89.2 Caldwell and Muller 2007, p. 79.

- ↑ "A similar quote from Göring in German from March 1943." luftkrieg-ederbergland.de. Retrieved: 17 August 2010.

- ↑ Bowman 2005, p. 119.

- ↑ Thomas and Ketley 2003, pp. 178–179.

- ↑ "List of Mosquito survivors." aussiemossie.asn.au. Retrieved: 17 August 2010.

- ↑ 94.0 94.1 Sharp and Bowyer 1971, pp. 393, 401–402.

- ↑ "The de Havilland Mosquito." wwiiaircraftperformance.org. Retrieved: 24 July 2008.

- ↑ Measured with smooth black finish rather than standard matte finish

- ↑ La Bonné, Frans. "The de Havilland Mosquito." World War II Warbirds, 9 February 2001. Retrieved: 21 April 2006.

- Bibliography

- Air Ministry. Pilot's Notes For Mosquito FB 6. Air Ministry. 1945. ISBN 978-0859790208

- Air Ministry. Pilot's Notes For Mosquito NF 38. Air Council. 1945. ISBN 978-0859790758

- Batchelor, John and Low, Malcolm. de Havilland Mosquito Manual. Plane Essentials. Publishing Solutions. 2008. ISBN 978-1-906589-00-4

- Birtles, Philip. Mosquito: A Pictorial History of the DH98. London: Jane's Publishing Company Ltd., 1980. ISBN 0-531-03714-2.

- Bishop, Edward. The Wooden Wonder. Shrewsbury, UK: Airlife Publishing Ltd., 3rd edition 1995. ISBN 1-85310-708-5.

- Bowman, Martin. de Havilland Mosquito (Crowood Aviation series). Ramsbury, Marlborough, Wiltshire, UK: The Crowwood Press, 2005. ISBN 1-86126-736-3.

- Bowman, Martin. Mosquito Bomber/Fighter-bomber Units 1942-45. Oxford, UK: Osprey Publishing, 1997. ISBN 1-85532-690-3.

- Bowman, Martin. Mosquito Fighter/Fighter-bomber Units of World War 2. Oxford, UK: Osprey Publishing, 1998. ISBN 1-85532-731-7.

- Bowman, Martin. Mosquito Photo-Reconnaissance Units of World War 2. Oxford, UK: Osprey Publishing, 1999. ISBN 1-85532-891-4.

- Bowyer, Chaz. Mosquito at War. Shepperton, Surrey, UK: Ian Allan Ltd., 4th impression 1979. ISBN 0-7110-0474-9.

- Bowyer, Michael J.F., Bryan Philpott and Stuart Howe. Mosquito (Classic Aircraft No. 7: Their History and How to Model Them). Cambridge, UK: Patrick Stephens Ltd., 1980. ISBN 0-85059-432-4.

- Bridgman, Leonard, ed. “The D.H.98 Mosquito.” Jane’s Fighting Aircraft of World War II. London: Studio, 1946. ISBN 1-85170-493-0.

- Buttler, Tony. British Secret Projects: Fighters & Bombers 1935-1950. Hinckley, UK: Midland Publishing, 2004. ISBN 1-85780-179-2.

- Cole, Roger. High Wycombe - Local History Series. Stoud, Gloucestershire, UK: Tempus Publishing Ltd., 2001. ISBN 0-7524-2290-1.

- Gilman J.D. and J. Clive. KG 200. London: Pan Books Ltd., 1978. ISBN 0-85177-819-4.

- Hardy, M.J. The de Havilland Mosquito. Devon, UK/New York: David & Charles (Publishers) Ltd./Arco Publishing, 1977. ISBN 0-7153-7367-6, (David & Charles) ISBN 0-668-04051-3 (Arco).

- Hinchcliffe, Peter. The Other Battle: Luftwaffe Night Aces vs Bomber Command. London: Zenith Press, 1996. ISBN 0-76030-265-0.

- Holliday, Joe. Mosquito! The Wooden Wonder Aircraft of World War II. Toronto: Doubleday, 1970. ISBN 0-77010-138-0.

- Hotson, Fred. The De Havilland Canada Story. Toronto: CANAV Books, 1983. ISBN 0-9690703-2-2.

- Howe, Stuart. Mosquito Portfolio. London: Ian Allan Ltd., 1984. ISBN 0-7110-1406-X.

- Jackson, Robert. Combat Legend; de Havilland Mosquito. Shrewsbury, UK: Airlife Publishing Ltd., 2003. ISBN 1-84037-358-X.

- Jones, R.C. de Havilland Mosquito: RAF Northern Europe 1936-45. London: Ducimus Books Ltd., 1970.

- Mason, Francis K. and Richard Ward. De Havilland Mosquito in RAF-FAA-RAAF-SAAF-RNZAF-RCAF-USAAF-French & Foreign Service. Canterbury, Kent, UK: Osprey Publishing Ltd., 1972. ISBN 0-85045-043-8.

- McKee, Alexander. The Mosquito Log. London: Souvenir Press Ltd., 1988. ISBN 0-285-62838-0.

- Miracle, Daniel B. and Steven L. Donaldson. ASM Handbook: Composites. Cleveland, Ohio: ASM International, 2001. ISBN 0-87170-703-9.

- Morgan, Hugh and John Weal. German Jet Aces of World War 2. London: Osprey Publishing Ltd, 1998. ISBN 1-85532-634-5.

- Mujumdar, A. S. Drying '92: Proceedings of the 8th International Drying Symposium. Toronto: Elsevier, 1992. ISBN 0-44489-393-8.

- Radinger, Will and Walter Schick. Me262 (German lang. ed.), Berlin: Avantic Verlag GmbH, 1996. ISBN 3-925505-21-0.

- Sasbye, Kjeld Mahler. Operation Carthage. Copenhagen: Den Danske Luftfartsskole, 1994. ISBN 87-985141-0-5.

- Scholefield, R.A. Manchester Airport. Stroud, UK: Sutton Publishing, 1998. ISBN 0-7509-1954-X.

- Scutts, Jerry. Mosquito in Action, Part 1. Carrollton, Texas: Squadron/Signal Publications Inc., 1993. ISBN 0-89747-285-3.

- Scutts, Jerry. Mosquito in Action, Part 2. Carrollton, Texas: Squadron/Signal Publications Inc., 1993. ISBN 0-89747-303-5.

- Shacklady, Edward. De Havilland Mosquito (Classic WWII Aviation , Volume 6). Bristol, UK: Cerberus Publishing Ltd., 2003. ISBN 1-84145-108-8.

- Sharp, C. Martin and Michael J.F. Bowyer. Mosquito. London: Faber & Faber, 1971. ISBN 0-571-04750-5.